The blue, 3D printed box with the cutout circle, hexagon, and other shapes is one of Carol Daguer’s first creations designed and produced in a makerspace.

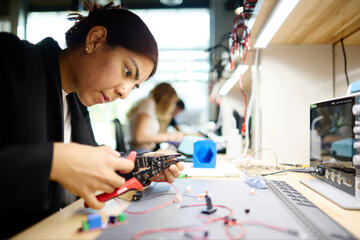

Daguer is one of the 16 students in the Makers and Innovators course, which introduces students to the inner workings of a makerspace, empowering them to expertly navigate the tools, software, and protocols of machine-shop environments and, more confidently, pursue design and prototyping projects outside of the classroom.

“I've learned a lot from this class because this class has given me the opportunity to actually be hands-on and, you know, prototype and see my designs come to life,” said Daguer, a mechanical engineering major and Honors College student.

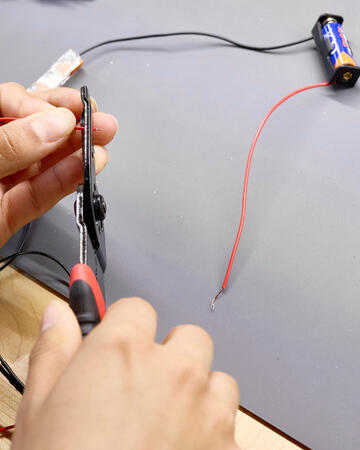

On a Friday morning, with light filtering softly through the wall-to-ceiling windows of the Advanced Engineering Building Maker Space, Daguer was hunched over at her workstation puzzling through the design of her first functional circuit.

“Our professor has encouraged us to make mistakes and to fail, but to get back up again and try it again,” Daguer said. “I have felt scared to try out a lot of the machines but they have made me feel, or they have instilled this confidence in me, that it's OK to fail as long as you try again and as long as you keep on being persistent. That's what's important.”

The Course: Makers and Innovators

“In the most general sense,” Wakefield said, “the idea of the class is to teach students how to use a makerspace.” AEB’s new Maker Space to be exact.

The honors-level course debuted this fall, with the Advanced Engineering Building’s new Maker Space serving as its laboratory. The goal is to open the pilot course — or, as instructor Camren Wakefield fondly calls it, "experimental" — to more students in coming semesters and expand access to the College of Engineering’s high-tech Maker Space.

The idea for the course developed after Maria Jerinic, Honors College associate dean, toured the space. She “could feel the potential,” she said, from the minute she walked into the room.

"In the Honors College, we emphasize the importance of cross-disciplinary work, collaboration, and creativity,” Jerinic said. “I imagined an Honors seminar — made up of students from many majors including engineering — that would let students pool the methods and approaches of their respective disciplines to solve problems and create."

Student projects have featured the use of an array of machines and tools including laser cutters, 3D and resin printers, soldering irons, and sheet metal tools.

“The AEB Maker Space is still working its way up to its full potential,” Wakefield said. “That’s part of what this class is for. To stretch its legs and see what it’s capable of.”

Students have also taken a handful of safety training workshops and have been introduced to the library’s makerspace and the Menhendall Machine Shop, where many College of Engineering students and registered student organizations work on projects.

“They can learn what’s expected in these kinds of spaces as they move on in their careers,” Wakefield said, adding that students get out of it what they put into it. He pointed out a newer generation of a 3D printer that was used in the making of Hailey’s Hand as an example of the caliber of projects possible in these facilities.

Who’s taking it?

“The class is absolutely geared toward people who have never set foot in a space before, in a machine shop or any sort of shop,” Wakefield said, adding that students of every major are welcome, from psychology to accounting to architecture.

For the first go-round, the class roster features a majority of engineering and computer science students with a sprinkling of students from other majors, including interior architecture and biochemistry.

The class is also a good starting point for engineering students gearing up to take on the capstone Senior Design class and competition. The competition, now in its 25th year, challenges students to build commercially viable prototypes and innovate solutions to engineering and computer science problems.

“The biggest thing is I want them to feel equipped so that they don't become overwhelmed by the idea of having to build this big project,” Wakefield said.

Anna Weigand, a double major in entertainment engineering and design (EED) and civil engineering, is still a year or two away from the capstone experience. But, with her previous EED lab experience and the knowledge she’s gaining in the Makers and Innovators course, she already feels prepared for that challenge.

“I did the LED circuitry project last week and that’s something I've been really wanting to get a grasp of,” Weigand said. “I’ve taken an electrical engineering class, but I haven't been able to apply that book knowledge yet. So, learning how to make a complete circuit or make an open circuit helps translate the math into real life. You can learn all the math, but once you see it happen, it becomes much more real and understandable.”

Who’s teaching it?

Wakefield, a graduate of UNLV’s EED program, was a natural fit to be the first instructor for the course.

As the EED lab coordinator, he teaches Introduction to Materials Science and Fabrication, the first class that students take in the major. It teaches hands-on design and creation and is held in the EED lab.

Wakefield also understands UNLV’s student body. As a former nontraditional student, he knows what it means to juggle school with a full-time job — not to mention side gigs as a production manager and technical director for theater companies including Super Summer Theatre and Santa Cruz Shakespeare.

The EED program recently earned accreditation from the Accreditation Board for Engineering and Technology (ABET). Wakefield describes it as a “hands-on program” that equips art students to be engineers and engineers to be art students.

“We are constantly exercising both sides of the brain,” he said. “We're also teaching you time management, project management and what it means to work with others. The entertainment industry is a very collaborative entity, and so we have to make sure the students can communicate with different mindsets, different skill sets, and different experience levels.”

He’s also brought a bit of that philosophy into the Makers and Innovators course. He’s refined project scope for students who have more experience with design and challenges students to determine how difficult their projects should be.

“I want them to want to push themselves,” he said, “but if it starts off too difficult, then they're going to do the bare minimum. If it starts off kind of easy, then I might be able to get the students to make it hard for themselves and then enjoy it. I really want the students to want to do these projects. We get a bit of product out of it and they might be proud of it in the end.”

What does AI have to do with this course?

“AI is a tool, and we talk about how these tools can be used appropriately and how they’ve been used inappropriately,” he said.

Wakefield is using the projects in the course to teach critical thinking, and project and time management.

“The current educational system emphasizes memorization — something that AI can just accomplish for you,” he said. “We have no interest in regurgitation.”

He requires students to journal throughout the entire project creation process, recording the time they worked, incorporating photographs and diagrams of the prototyping process, and documenting if and how plans changed along the way.

“It’s very present note taking versus writing a reflection paper or writing a summary on something that already exists,” he said. “Was it easier than they thought? What did they get out of it? Did they learn anything? Did everything work out perfectly?”

Chances are, no. And Wakefield prefers it that way. The bigger lesson — the one Daguer learned as she persisted to create a second, and more complicated circuit — is not something AI can teach you.

“I think the class would be pretty boring if students got it right the first time all the time,” said Wakefield. “We’re training up the next generation of thinkers and creators, and sometimes the best inventions come after a bit of trial and error.”