Principal Investigator/Researcher

Dr. Mehdi Ahmadian, Virginia Tech

Project Description

Top-of-Rail Friction Modifiers (TORFM) behave as a third body layer in between the wheel and rail and is applied to reduce wheel and rail wear while preserving a stable traction condition. An added benefit of TORFM is that it is estimated that it can reduce fuel consumption by controlling friction, although we are not aware of any proven data in support of this. Although widely used by the U.S. Class I railroads, there exists no proven method for determining, qualitatively or quantitatively, how the amount of TORFM and rail/wheel wear are related. Simply put, would increasing TORFM amount by a factor of two reduce wheel/rail wear and damage by one-half? How would such doubling effect traction or the longevity of TORFM on the wheel/rail surface? In this study, the VT-FRA roller rig is used to perform a series of tests under highly controlled conditions to shed more light on answering these questions. A series of controlled experiments are designed and performed in order to investigate the potential factors that may influence the traction performance. The wheel surface profile is measured by a high-precision, 3D, laser profiler to measure the progression of wheel wear for the duration of the experiments. The results indicate that it takes as much as 50% to 70% longer time for the traction force (traction coefficient) to reach a condition that is the same as the unlubricated rail when compared between lightly-, moderately-, and heavily-lubricated conditions. The results further indicate that wear generation is delayed significantly among all lubrication conditions—even, the lightly-lubricated—when compared with the unlubricated condition. A further evaluation of the results and additional tests are needed to provide further insight into some of the preliminary results that we have observed thus far.

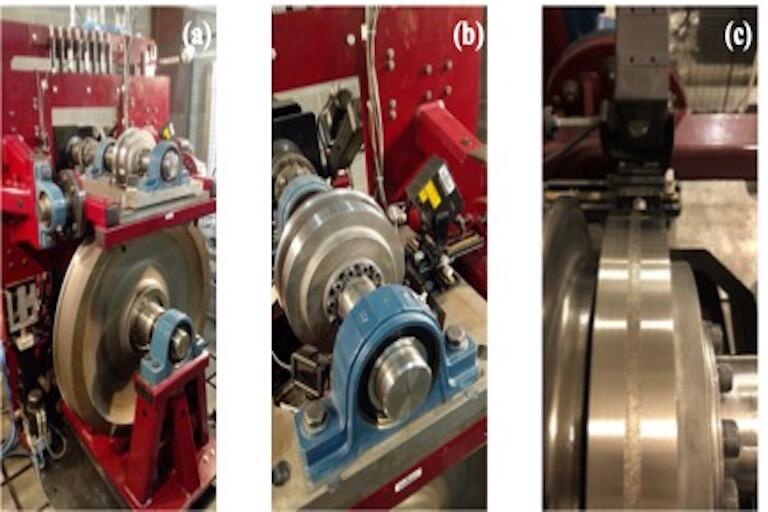

An experimental study of the effect of Top-of-Rail Friction Modifiers (TORFM) in quantities ranging from a small to large amount on the traction and the progression of wheel-rail wear has been performed using the Virginia Tech-FRA (VT-FRA) roller rig, shown below. A series of highly controlled experiments are performed in order to investigate the potential factors related to the quantities of friction modifiers on the traction performance. Besides, the wheel surface profile is measured by the high-precision 3D-laser profiler to measure the progression of wheel wear for the duration of the experiments. The results indicate that it takes a much longer time for the traction forces (coefficients) to reach a condition that is the same as the unlubricated rail when compared between lightly-, moderately-, and heavily-lubricated conditions. The results further indicate that wear generation is delayed significantly among all lubrication conditions—even, the lightly-lubricated—when compared with the unlubricated condition.

This study intends to extend our past studies to more precisely quantify the relationship between the rail lubrication condition and the amount of rail and wheel wear that occurs over time, for various traction and wheel load conditions.

Implementation of Research Outcomes

There are no proven and controlled methods for assessing the relationship between the amount of lubrication that is applied to the rail/wheel and the reduced wear that it is expected to yield. This study will provide a scientific evaluation of the relationship between the track lubrication and reduction in wear, in repeatable and controlled conditions that emulate field conditions. It will also provide an evaluation of how increasing wheel load would contribute to any additional wheel and rail wear. Such an evaluation will allow for conducting an economic assessment of increasing railcar tonnage, which is desired by most of the railroads.

Impacts/Benefits of Implementation

The friction modifier materials that are used on top of the rail to control the rolling friction between the wheel and rail add a substantial amount to the operation of the U.S. railroads. Among the U.S. Class I railroads, such costs are estimated to amount to nearly $100M per year. Yet, there are no proven methods to quantify the benefits of rail lubrication, toward establishing a cost-to-benefit determination. This study will provide a valid and scientific assessment of how much economic benefits the railroads can expect to receive for the annual investment that they make in top of rail friction modifiers. This would lead to a more informed and economic-based decision by the U.S. railroad.

Web Links

The VT-FRA roller rig (a) along with the side and top view of a laser scanner that is used for precise measurement of wheel wear (shown in (b) and (c), respectively)